The future market to not go to do cashmere sweater price war victims, then our only way out is to make cashmere sweaters should be quality, do not go to do cashmere sweater price advantage, only do a good job of our own quality advantage, there is no best only better, the following is the quality of the quality control of the six steps:

1, the selection of raw materials and suppliers

The quality of cashmere yarn directly affects the quality of the product, and the conditions to be able to do testing on the quality of the yarn, including weight, moisture return rate, quality control components, physical function, and appearance quality. Before the purchase of yarn should be investigated and appraised, the best choice of fixed cooperation spinning mill, to ensure stable yarn quality. In addition, when purchasing yarn, pay attention to the moisture content. Due to climatic reasons, the actual moisture content and standardized moisture content have a certain difference, beware of air humidity can also be sold, you can think about the processing of raw materials to standard weight for accounting.

The selection of raw material suppliers is particularly important. For example, choose Ordos cashmere, Yu Zhengrong cashmere sweater, Deer King cashmere sweater, and other major brands with the same raw material suppliers, choose the same major brands with the same grade or higher grade yarn, niche brands with the same or better cashmere yarn produced out of cashmere sweater prices, compared with the major brands have an absolute advantage, in particular, to choose to have a strong concept of quality of the cashmere sweater processing plant. Of course, it is best to have their own production factories, if a factory environment is dirty and poor, the quality of the finished product produced can be ensured? A little skeptical? Not to do processing wool sweater factories can do cashmere sweater processing. Because the after-treatment of cashmere sweaters and ordinary wool sweaters is not the same. So we have to carefully and conditionally select the production supplier. Company QC, affairs, and other relevant parts of the processing supplier’s company qualifications, staff ratio, machinery and equipment, quality awareness, working environment, and other aspects of the evaluation to confirm.

2, strengthen the effective supervision of the production process

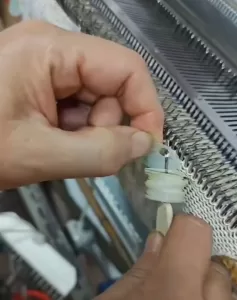

The cashmere sweater processing production process is basically: horizontal machine – weaving piece – over the mouth – hand sewing – lighting –Washing and drying – (flatbed) – lighting – ironing – – degree ruler – checking – – the production process of cashmere sweater processing is basically -Measurement – Checking – Hair – Measurement – Packing. Requirements for each process in the factory should be viewed and supervised, factory QC can not just stay in the finished product to see, but put more energy into the supervision of the production process. Discover the doubt in the scene to deal with, good goods are produced, as long as the production site finds the question, and deals with the question, in order to prevent the waste of raw materials and labor, but also not to affect the delivery date. As a QC, probably know the main points of each process, know the quality problems that are likely to occur in the production process, target to adopt some ways to prepare, but also be able to prevent problems before they occur.

3, cashmere sweater processing after treatment

Cashmere Sweater is a high-level good, customer demand garments soft, smooth, velvet, feel, and color to achieve the best results. How to achieve these needs? The most important thing is to wash shrinkage treatment. This is also can do ordinary wool sweater manufacturers may not be able to do cashmere sweater processing reasons. The cashmere sweater washing shrinkage link should be based on the characteristics of the goods to select the appropriate detergent, softener, and other additives, the development of washing and shrinkage of the technical parameters, so that the cashmere sweater velvet, feel, color, and luster to achieve the best effect to appear. Before washing the big goods, we must try to wash a small piece of cloth first, according to the effect of the cloth washed out, and then develop the washing technology parameters. When drying, the clothes should be thoroughly shaken. The drying time should not be too long, to reduce the drying of the shirt body in the cylinder tumbling in conflict with each other and continuing to fluff and affect the feel. Usually, adopt the anti-shrinking anti-drying. As long as after a long time of exploration, and constantly summarize the good washing shrinkage process.

4, the weight of the garment

Cashmere sweater is a gram for the unit of accounting offer, weight control is particularly important and sensitive. In the sampling, the design stage should estimate the approximate weight of the garment. The weight determines whether the price range of the garment is in line with the customer’s psychological price range, and the knitting technology is used to make adjustments. In the production of large quantities of goods, we pay attention to controlling the loss of each process and control all the tangible losses. There is also an intangible loss, such as washing loss, cashmere in the washing process to wash away the yarn on the grease, heavy metals, falling hair, etc… In addition, the raw material yarn is usually a standardized rate of return discounted portion, while the cashmere products are the actual weight of the finished product accounting.

5. Accessories

Cashmere sweaters with the accessories such as buttons, zippers, ribbons, beads, etc. should be strictly checked and tested to prevent color loss, shrinkage, and breakage. The position of the main label and washing label on the body of the shirt should be correct, and should not be missed or wrongly ordered. A garment with excellent workmanship and quality should never be affected by a small auxiliary material.

6. After-sales service

After-sales service is an extension of the quality of goods, is each cashmere sweater brand establishes an image in the minds of customers, but also the concept of the company’s services to customers, especially in the domestic market, the after-sales service of goods is particularly important. On the consumer response to the information to be collected in a timely manner, analysis, and improvement. On the customer can repair to do a good job in a timely manner cashmere sweater free repair and so on. This is extremely favorable to improve the level of goods and the company’s cashmere sweater brand image.

Through the detailed management of the above 6 steps, cashmere sweater production can more easily ensure quality advantage and realize steady development. High-quality cashmere sweaters have a huge competitive advantage in the global market, especially in China, a major global manufacturing country. With its high-quality raw material supply and excellent processing technology, China has become the global leader in cashmere sweater manufacturing by occupying 90% of the global cashmere sweater manufacturing share.

The Cashmere sweater is known as one of the essential clothing for everyone in winter, and its unique warmth and soft texture are loved by consumers. Whether in the domestic market or cross-border e-commerce, a cashmere sweater is one of the popular commodities. The biggest and best companies doing cross-border e-commerce in China are often those that focus on product quality and have strong production capacity and supply chain advantages. At the same time, for cross-border e-commerce, the reasonable use of Google search cashmere sweater hot keywords, and SEO optimization of the article, you can let more potential customers search for this article, and then understand and buy cashmere sweater, to promote the sales and development of enterprises.

To summarize, through scientific quality control, effective supervision of the production process, reasonable post-processing, strict weight control of garments, a high-quality selection of accessories, and considerate after-sales service, the cashmere sweater industry is able to stand out in the fierce market competition and achieve greater success. As a global manufacturing power, China dominates the cashmere sweater manufacturing industry, providing high-quality cashmere sweater products to global consumers. Meanwhile, in the field of cross-border e-commerce, Chinese enterprises are able to attract more overseas customers and achieve further expansion and development by reasonably utilizing Google to search for hot keywords for cashmere sweaters.