First, a little background:

My grandmother, two uncles, and my mom are all in the wool sweater manufacturing business. They have over thirty years of experience in the industry, and I grew up in a wool sweater factory. There was a time when I even slept under the machines. Today, woolen sweaters are the main industry of my family. My uncle runs a sweater knitwear factory, while I opened a foreign trade company in 2019 to supply woolen products to foreign customers.

Wool sweater quality chapter

- A sweater that feels warm to the touch may not be of good quality, and most wool sweaters with a high acrylic content usually exhibit this characteristic. On the contrary, sweaters that feel a little cooler to the touch may use better quality yarns and have a better warmth-retaining effect.

- High-quality sweaters will feel cool and slightly hard to the touch, but once worn, they will feel warm and soft when touched again.

- Soft can not be used as the only standard to judge the quality of the sweater, because some processing methods can make the poor quality of the sweater becomes soft and smooth.

- The softness of a sweater sometimes depends on the stitch pattern. For example, with the same yarn, a top, and a bust may be knitted differently, with the top being softer and the bust being slightly stiffer and more contoured.

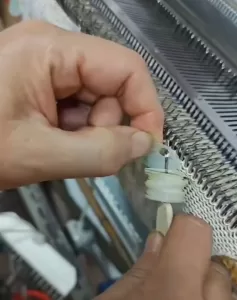

- The machine’s crochet hook arrangement density will also affect the hardness of the fabric. Different machines weave fabrics with slight differences in the strict sense of the word.

- Imitation cashmere is one of the worst quality and cheapest knitwear. Imitation cashmere clothing appears white and long in shape when first knitted, shrinks into small pieces after dyeing and processing, and is very soft to the touch.

- Although the cost of imitation cashmere is very low, the material used is not good, but the imitation cashmere clothing is not easy to fade or shrinkage.

- There is no one hundred percent cashmere sweater on the market because cashmere itself can not be knitted into a line, you must add other materials to form yarn. So claiming 100 percent pure cashmere sweater, its cashmere component is usually between 80% and 90%. (Normally we would just say 100% all cashmere or all wool because it would be tedious to explain to an uninformed customer.)

- A way to judge the quality of knitwear yarn is to pull a thread, and then burned with fire and crushed it with your fingers. If the yarn is powdered after burning, and there is an odor of burnt protein, it means that the quality is good. If the burning was the inconsistent size of the slag block, then the quality of the yarn is general.

- There is no not puckering knitwear, only easy-to-puckering and not-easy-to-puckering points.

- Pilling and knitwear quality are not directly related. Some use real cashmere to knit the clothes but are easy to ball, while some use clothes made with real cashmere that are prone to pilling, while some clothes made with ordinary yarns are not prone to pilling.

- To test whether the knitwear is prone to pilling method is to pick up the knitwear, in a place quickly with the thumb in a circle friction for a few seconds, to observe the surface of whether there are traces of hair. If there are traces, it is easy to pill; if there are no traces, it is not easy to pill.

- Light-colored wool sweaters usually cost more to manufacture, while black wool sweaters can be mixed with some lower-quality wool due to their darker color, so the cost is relatively lower. However, this is not an absolute rule.

- Cashmere clothing is more prone to pilling than ordinary clothing because wool itself is a kind of ultra-fine fiber, which is prone to produce hairballs in friction. However, in the processing of the factory, it is possible to minimize the pilling of cashmere clothing by increasing the twist of the yarn and denser needle rows.

- The content of cashmere composition even experienced workers is difficult to accurately judge, they can only confirm whether it contains cashmere, and the specific content ratio needs to be further professional testing.

- Qualified cashmere sweaters are usually steamed at a high temperature of about 120 degrees before leaving the factory, so unless they are of extremely low quality, they can generally be worn close to the skin without causing skin allergies or discomfort.

- Regarding the testing of the composition of cashmere sweaters, there are national specialized agencies that carry out the testing of the relevant components, and the testing cost is about a few hundred dollars. Ordinary consumers can also be tested if necessary. As there are many fake and imitation products in the market, some merchants will send clothing involving wool and cashmere for testing and obtaining test reports.

- Regarding the ingredient test reports, at least merchants who are willing to spend the cost of the tests show that they are sincere, but I have also heard of cases where the samples and the subsequent clothing do not match, so they need to be believed in moderation and not accepted wholesale.

- Many people have an unrealistic fantasy about clothing that costs two or three thousand dollars, always thinking that such clothing must be perfect. However, the actual situation is not so, even if the value of two or three million dollars worth of clothing, sometimes there will be flaws. Some of these flaws are unavoidable in the process, such as the knitted cuffs can only be as flat as possible. While other imperfections are errors and flaws tolerated by the product itself.

By knowing these 19 facts about the quality of wool sweaters, you can better judge the quality of your wool sweaters and choose a high-quality product that is right for you. These facts are based on my years of experience in the wool sweater industry and my family’s background in the industry. I hope you find this information helpful.