When sweater buyers source sweaters, depending on the sweater trend, they need to carry out a series of detailed and complex tasks to ensure that the purchased products can meet the market demand and meet the expected quality standards. Below are the detailed nine steps in the sourcing process for YZRCA sweater buyers:

- Market Research:

Buyers will first conduct comprehensive market research to understand the current trends, consumer needs and competitive landscape of the wool sweater market. They will attend fashion exhibitions, observe popular elements on fashion blogs and social media, as well as collect relevant industry reports and market data. - Determine sourcing objectives:

Based on market research, buyers will determine sourcing objectives, including the desired styles, colors, fabrics and quantities. They will make purchasing plans according to the season, region and target customer groups. - Select quality suppliers:

Buyers will contact several potential suppliers or manufacturers to understand their product range, production capacity and quality control system. The buyer will then shortlist suitable suppliers and conduct in-depth cooperation negotiations with them. - Sample sourcing and evaluation:

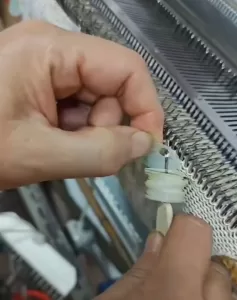

The buyers will request samples from the selected suppliers and then carefully evaluate and quality check the samples. They will check whether the weave, workmanship, fabric quality and color of the woolen sweaters meet the requirements, and also test their comfort and wearability. - Negotiate price and terms:

After making sure that the samples meet the requirements, buyers will negotiate prices and delivery conditions with suppliers. They will strive for the best price and ensure that the delivery time and quality standards meet expectations. - Order placement and production follow-up:

Once an agreement is reached, buyers will place orders and follow up on production progress. They will keep in close contact with suppliers to ensure that production is progressing smoothly and that any potential problems are resolved in a timely manner. - Quality control gatekeeping:

The buyer will send staff to the supplier’s factory to conduct on-site quality checks to ensure that the wool sweaters are produced to standard. They will sample finished products and work with suppliers to resolve quality issues. - Logistics and shipment:

Once the production of the sweaters is completed, the buyer will arrange logistics and shipment to ensure that the products are delivered to the point of sale or warehouse on time. - Sales tracking:

The buyer will keep tracking the sales of the sweaters to understand the heat of the products and consumer feedback. Based on the sales situation, the buyer will adjust the purchasing strategy to ensure the products continue to sell well.

Woolen sweater buyers play a key role in the entire sourcing process, and their decisions and efforts have a direct impact on the quality and sales of the final product. They need to possess extensive industry knowledge and market insights, as well as good working relationships with suppliers to ensure the prosperity and growth of the wool sweater industry.